Massively trace backwards thermal-hydraulic regime for district heating network

Source:R/tracebw.R

tracebw.RdTrace values of thermal-hydraulic regime (temperature, pressure, flow rate, and other) in the bunched pipeline against the flow direction using user-provided values of specific heat loss power.

Algorithm also suits for partially measurable district heating network with massive data lack conditions, when there are no temperature and pressure sensor readings on the majority of terminal nodes.

Usage

tracebw(

sender = 6,

acceptor = 7,

temperature = 70,

pressure = pipenostics::mpa_kgf(6),

flow_rate = 20,

d = 100,

wth = 8,

len = 72.446,

loss = 78.4,

roughness = 0.001,

inlet = 0.5,

outlet = 1,

method = "romeo",

opinion = "median",

verbose = TRUE,

csv = FALSE,

file = "tracebw.csv"

)Arguments

- sender

identifier of the node which heat carrier flows out. Type: any type that can be painlessly coerced to character by

as.character.- acceptor

identifier of the node which heat carrier flows in. According to topology of test bench considered this identifier should be unique for every row. Type: any type that can be painlessly coerced to character by

as.character.- temperature

sensor-measured temperature of heat carrier (water) sensor-measured on the terminal acceptor node, [°C]. Use

NA_float_s for (terminal) nodes without temperature sensor. Type:assert_double.- pressure

sensor-measured absolute pressure of heat carrier (water) inside the pipe (i.e. acceptor's incoming edge), [MPa]. Type:

assert_double.- flow_rate

sensor-measured amount of heat carrier (water) on terminal node that is transferred by pipe (i.e. acceptor's incoming edge) during a period, [ton/h]. Type:

assert_double. UseNA_float_s for nodes without flow rate sensor.- d

outside diameter of pipe (i.e.diameter of acceptor's incoming edge), [mm]. Type:

assert_double.- wth

wall thickness of pipe, [mm]. Type:

assert_double.- len

pipe length (i.e. length of acceptor's incoming edge), [m]. Type:

assert_double.- loss

user-provided value of specific heat loss power for each pipe, [kcal/m/h]. Values of the argument can be obtained experimentally, or taken from regulatory documents. Type:

assert_double.- roughness

roughness of internal wall of pipe (i.e. acceptor's incoming edge), [m]. Type:

assert_double.- inlet

elevation of pipe inlet, [m]. Type:

assert_double.- outlet

elevation of pipe outlet, [m]. Type:

assert_double.- method

method of determining Darcy friction factor:

romeovatankhahbuzzelli

Type:

assert_choice. For more details seedropp.- opinion

method for aggregating values of regime parameters on each node for the next tracing step:

meanvalues of parameter are averaged before the next tracing step

medianmedian of parameter values are used for the next tracing step

Type:

assert_choice.- verbose

logical indicator: should they watch tracing process on console? Type:

assert_flag.- csv

logical indicator: should they incrementally dump results to csv- file while tracing? Type:

assert_flag.- file

name of csv-file which they dump results to. Type:

assert_characterof length 1 that can be used safely to create a file and write to it.

Value

data.frame containing results (detailed log) of tracing in

narrow format:

nodeTracing job. Identifier of the node which regime parameters is calculated for. Values in this vector are identical to those in argument

acceptor. Type:assert_character.tracingTracing job. Identifiers of nodes from which regime parameters are traced for the given node. Identifier

sensoris used when values of regime parameters for the node are sensor readings. Type:assert_character.backwardTracing job. Identifier of tracing direction. It constantly equals to

TRUE. Type:assert_logical.aggregationTracing job. Identifier of aggregation method: span, median, mean, or identity. Type:

assert_character.lossTraced thermal hydraulic regime. Normative specific heat loss power of adjacent pipe, [kcal/m/h]. Type:

assert_double.fluxTraced thermal hydraulic regime. Normative heat flux of adjacent pipe, [W/m²]. Type:

assert_double.QTraced thermal hydraulic regime. Normative heat loss of adjacent pipe per day, [kcal]. Type:

assert_character.temperatureTraced thermal hydraulic regime. Traced temperature of heat carrier (water) that is associated with the node, [°C]. Type:

assert_double.pressureTraced thermal hydraulic regime. Traced pressure of heat carrier (water) that is associated with the node, [MPa]. Type:

assert_double.flow_rateTraced thermal hydraulic regime. Traced flow rate of heat carrier (water) that is associated with the node, [ton/h]. Type:

assert_double.jobTracing job. Value of tracing job counter. Type:

assert_count.

Type: assert_data_frame.

Details

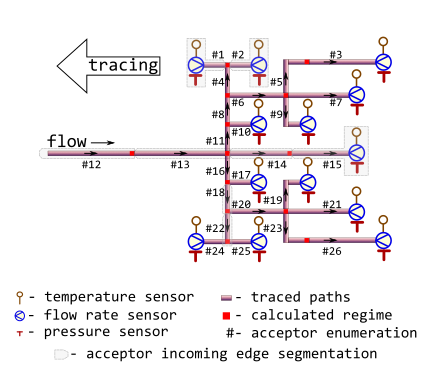

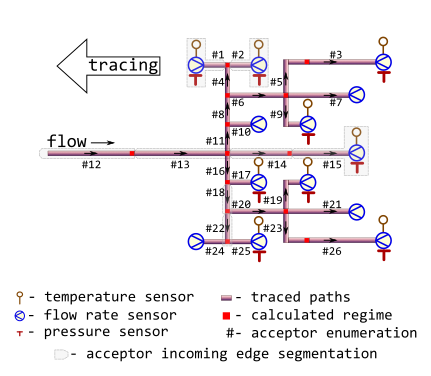

They consider the topology of district heating network represented by

m325nxdata:

The network may be partially sensor-equipped too:

In latter case no more than two nodes must be equipped with pressure and temperature sensors whereas for other nodes only flow rate sensors must be installed.

Tracing starts from sensor-equipped nodes and goes backwards, i.e against the flow direction.

Though some input arguments are natively vectorized their individual values

all relate to common part of district heating network, i.e. associated with

common object. It is due to isomorphism between vector representation and

directed graph of this network. For more details of isomorphic topology

description see m325nxdata.

Before tracing starts for the next node, previously calculated values of thermal-hydraulic parameters are aggregated by either averaging or by median. The latter seems more robust for avoiding strong influence of possible outliers which may come from actual heating transfer anomalies, erroneous sensor readings or wrong pipeline specifications.

Aggregation for values of flow rate at the node is always sum.

See also

Other Regime tracing:

dropg(),

dropp(),

dropt(),

m325tracebw(),

m325tracefw(),

m325traceline(),

tracefw(),

traceline()

Examples

library(pipenostics)

# It is possible to run without specification of argument values:

tracebw()

#>

#> 2025-09-19 11:38:17.204666 tracebw | start backward tracing; segments 1;

#> 2025-09-19 11:38:17.204666 tracebw | start job; job 0;

#> 2025-09-19 11:38:17.204666 tracebw | now process; 1 node(s); [7]

#> 2025-09-19 11:38:17.204666 tracebw | seen tracing; [1/1] are TP-sensor-equipped;

#> 2025-09-19 11:38:17.204666 tracebw | tracing loss;;

#> 2025-09-19 11:38:17.204666 tracebw | OK! Specific heat loss power traced from 1 nodes;[7];

#> 2025-09-19 11:38:17.204666 tracebw | tracing heat flux;;

#> 2025-09-19 11:38:17.204666 tracebw | OK! Heat flux traced from 1 nodes;[7];

#> 2025-09-19 11:38:17.204666 tracebw | tracing heat loss per day;;

#> 2025-09-19 11:38:17.204666 tracebw | OK! Heat loss per day traced from 1 nodes;[7];

#> 2025-09-19 11:38:17.204666 tracebw | tracing temperature;;

#> 2025-09-19 11:38:17.204666 tracebw | OK! Temperature traced from 1 nodes;[7];

#> 2025-09-19 11:38:17.204666 tracebw | tracing pressure;;

#> 2025-09-19 11:38:17.204666 tracebw | OK! Pressure traced from 1 nodes;[7];

#> 2025-09-19 11:38:17.204666 tracebw | tracing flow_rate;;

#> 2025-09-19 11:38:17.204666 tracebw | finish job; job 0; processed node(s) 1

#> 2025-09-19 11:38:17.204666 tracebw | finish backward tracing;;

#> node tracing backward aggregation loss flux Q temperature

#> 1 7 sensor TRUE identity 78.4 290.2324 136314.4 70

#> span 7 sensor TRUE span 0.0 0.0000 0.0 0

#> median 7 sensor TRUE median 78.4 290.2324 136314.4 70

#> mean 7 sensor TRUE mean 78.4 290.2324 136314.4 70

#> pressure flow_rate job

#> 1 0.588399 20 0

#> span 0.000000 20 0

#> median 0.588399 20 0

#> mean 0.588399 20 0

# Consider isomorphic representation of District Heating Network graph:

DHN <- m325nxdata

# * Adapt node identifiers for ordering representation simplification:

DHN[["sender"]] <- sprintf("N%02i", DHN[["sender"]])

DHN[["acceptor"]] <- sprintf("N%02i", DHN[["acceptor"]])

# * Provided actual values of specific heat loss power

# (say, field measurements) for each pipe in DHN, [kcal/m/h]:

actual_loss <- c(

96.2360000000000, 96.2880000000000, 70.5840000000000,

116.0449431257620, 70.7340165868372, 96.2114863150603,

78.4000000000000, 116.0158816197730, 28.1152000000000,

24.9182000000000, 116.6790503515620, 152.8311474487970,

152.7893321276950, 96.7331745004449, 96.6000000000000,

116.6668284940720, 24.9596000000000, 115.9228232554340,

28.1658000000000, 96.1226072815915, 77.8240000000000,

115.9455144867840, 70.6899252508703, 96.1840000000000,

96.2360000000000, 70.5400000000000

)

# * Remove inappropriate attributes of the graph:

DHN.1 <- DHN[,

setdiff(

colnames(DHN),

c("a", "year", "insulation", "laying", "beta", "exp5k")

)

]

# * Trace thermal-hydraulic regime for DHN:

tracebw_report <- do.call(

"tracebw", c(as.list(DHN.1), list(loss = actual_loss), verbose = FALSE)

)

# * If the actual values of specific heat loss power presented above are

# close to those in Minenergo-325, then the results of regime tracing match

# the normative procedure:

m325_report <- do.call("m325tracebw", c(as.list(DHN), verbose = FALSE))

stopifnot(

all.equal(tracebw_report$temperature, m325_report$temperature, tol = 1e-4),

all.equal(tracebw_report$pressure, m325_report$pressure, tol = 1e-4),

all.equal(tracebw_report$flow_rate, m325_report$flow_rate, tol = 1e-4)

)