Calculate normative heat loss of pipe through the thermal insulation that is legally affirmed by Minenergo Order 325.

Usage

m325nhl(

year = 1986,

laying = "underground",

exp5k = TRUE,

insulation = 0,

d = 700,

temperature = 110,

len = 1,

duration = 1,

beta = FALSE,

extra = 2

)Arguments

- year

year when the pipe is put in operation after laying or total overhaul. Type:

assert_integerish- laying

type of pipe laying depicting the position of pipe in space:

air,channel,room,tunnel,underground.

Type:

assert_subset.- exp5k

pipe regime flag: is pipe operated more that 5000 hours per year? Type:

assert_logical.- insulation

insulation that covers the exterior of pipe:

0no insulation

1foamed polyurethane or analogue

2polymer concrete

Type:

assert_integerandassert_subset.- d

nominal (outside) diameter of pipe, [mm]. Type:

assert_double.- temperature

temperature of heat carrier (water) inside the pipe, [°C]. Type:

assert_double.- len

length of pipe, [m]. Type:

assert_double.- duration

duration of heat loss, [h]. Type:

assert_double.- beta

should they consider additional heat loss of fittings? Type:

assert_logical.- extra

number of points used for temperature extrapolation:

2,3, or4. Type:assert_choice.

Value

Normative heat loss of cylindrical pipe during duration,

[kcal]. If len of pipe is 1 m (meter) as well as

duration is set to 1 h (hour) (default values) then the

return value is also the specific heat loss power,

[kcal/m/h], prescribed by

Minenergo Order 325.

Type: assert_double.

Details

Temperature extrapolation and pipe diameter interpolation are leveraged

for better accuracy. Both are linear as it dictated by

Minenergo Order 325.

Nevertheless, one could control the extrapolation behaviour by extra

argument: use lower values of extra for soft curvature near

extrapolation edges, and higher values for more physically reasoned

behaviour in far regions of extrapolation.

See also

Other Minenergo:

m278hlair(),

m278hlcha(),

m278hlund(),

m278insdata,

m278inshcm(),

m278soildata,

m325beta(),

m325nhldata,

m325nvl(),

m325nxdata

Examples

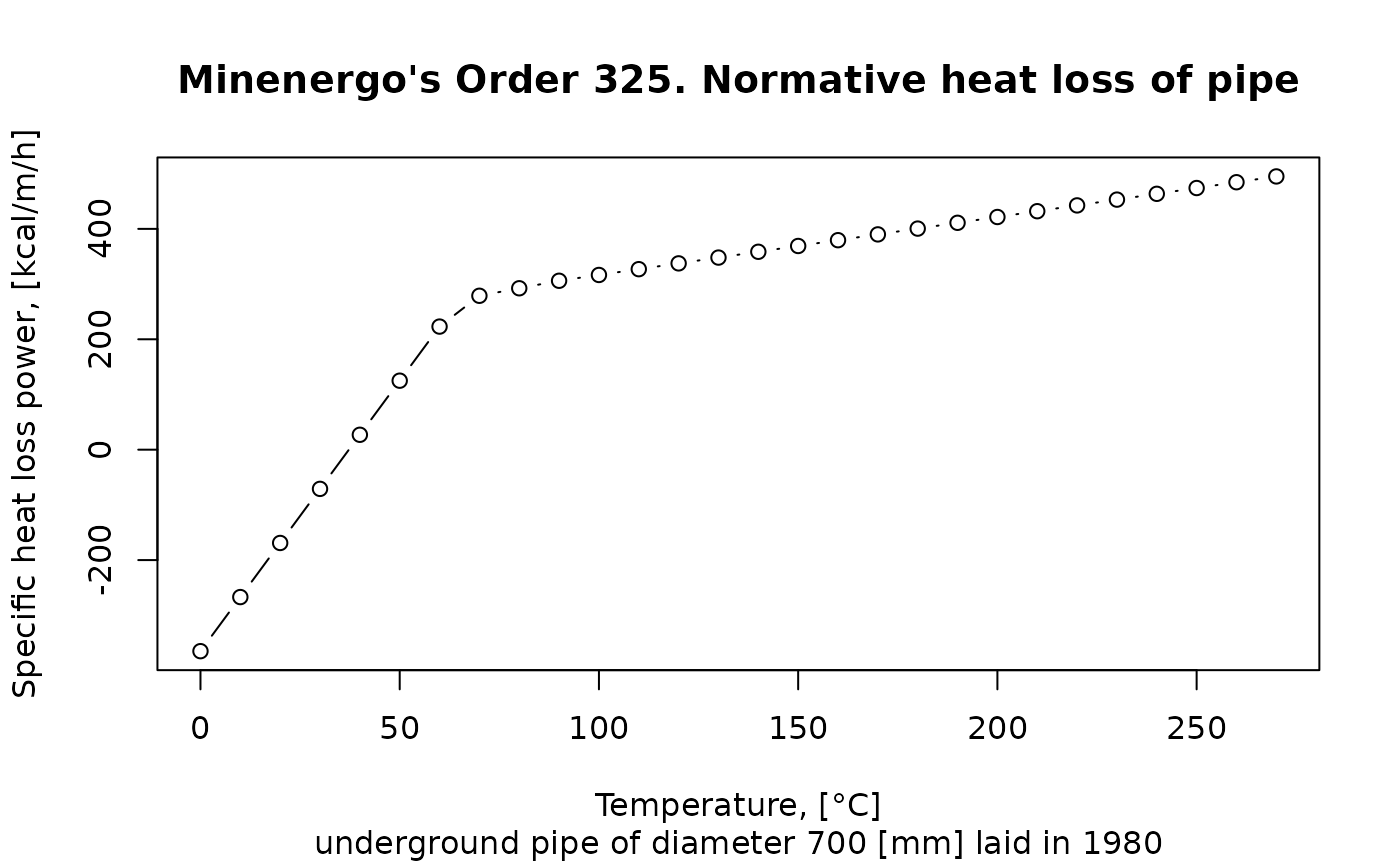

library(pipenostics)

## Consider a one-meter length pipe with

pipe_diameter <- 700.0 # [mm]

pipe_dating <- 1980

pipe_laying <- "underground"

## Linear extrapolation adopted in Minenergo's Order 325 using last two

## points:

operation_temperature <- seq(0, 270, 10)

qs <- m325nhl(

year = pipe_dating, laying = pipe_laying, d = pipe_diameter,

temperature = operation_temperature

) # [kcal/m/h]

plot(

operation_temperature,

qs,

type = "b",

main = "Minenergo's Order 325. Normative heat loss of pipe",

sub = sprintf(

"%s pipe of (outside) diameter %i [mm] laid in %i",

pipe_laying, pipe_diameter, pipe_dating

),

xlab = "Temperature, [°C]",

ylab = "Specific heat loss power, [kcal/m/h]"

)

## Consider heat loss due fittings:

operation_temperature <- 65 # [°C]

m325nhl(

year = pipe_dating, laying = pipe_laying, d = pipe_diameter,

temperature = operation_temperature, beta = c(FALSE, TRUE)

) # [kcal/m/h]

#> [1] 272.0 312.8

## Consider heat loss due fittings:

operation_temperature <- 65 # [°C]

m325nhl(

year = pipe_dating, laying = pipe_laying, d = pipe_diameter,

temperature = operation_temperature, beta = c(FALSE, TRUE)

) # [kcal/m/h]

#> [1] 272.0 312.8